24??media Fundamentals Explained

24??media Fundamentals Explained

Blog Article

24??media - Truths

Table of ContentsThe 45-Second Trick For 24??media7 Simple Techniques For 24??mediaThe Only Guide for 24??mediaTop Guidelines Of 24??media24??media - Questions

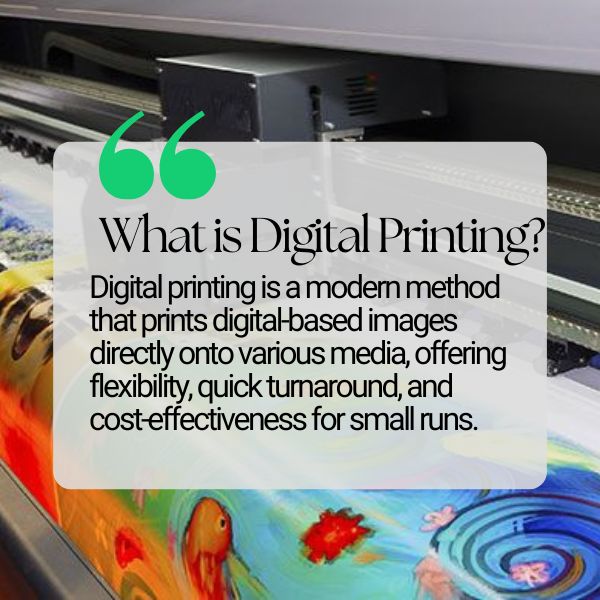

Developments in print innovation are altering the communications playing field when it involves quality, cost and innovative capacities. Countered printing and electronic printing are the major procedures by which print work are taken on both making use of four-color printing techniques. Each alternative has its advantages, supplying various strategies to fulfill the needs of varied manufacturing jobs.

Normally, this has actually been one of the most regular strategy for exactly preserving color matches, making it excellent for print runs that just call for static printing such as pre-printed kinds, brochures, leaflets, calling card, and bulk postcard mailings. Nonetheless, due to the static nature of litho printing, it is not ideal for variable print pieces that will be mailed to individual recipients such as statements, letters, and individualized postcards.

How 24??media can Save You Time, Stress, and Money.

The current innovations in print technology are helping to bring several of offset's advantages into the electronic printing world really altering the face of contemporary printing! There are some crucial distinctions in between Offset Printing and Digital Printing (Custom Boxes). This overview shows the advantages and drawbacks of each printing technique. There is an obvious and growing variety of advantages to using the digital print process.

Today's digital print equipment is among the most sophisticated on the marketplace. Here are several of the biggest benefits of utilizing digital printing: control the digital print room, with full-color printing completed in one procedure and flawlessly published directly from a print file. Without a lengthy set-up process, the calibration time of a details work is reduced, adding to quicker print time and total shipment.

The inkjet printing procedure has actually aided to reinvent the sector in addition to the quality and speed of the output. The current inkjet modern technology can publish on typical balanced out stocks with boring, silk, and shiny coatings. Top notch electronic print coupled with software-managed color monitoring practices includes optimum worth to print items and makes manufacturing procedures extra dependable than balanced out.

The 8-Second Trick For 24??media

(https://www.pubpub.org/user/24-media)

Exact quantities of ink and printer toner are made use of to stay clear of waste. Environmentally friendly and eco-friendly inks and toners are additionally readily available for more lasting printing. Digital print likewise removes the demand to wash plates or blankets with unsafe chemicals at the end of the printing process. As the high quality of electronic print solutions raises, the advantages end up being increasingly apparent and helpful.

Variable information helps businesses reach their exact clients and target market with uniquely-created and personalized material. As technology enhances, the high quality of digital printing has actually come to be second-to-none, with better detail, shade match abilities and general accuracy. Without the need to wash plates or make use of excess ink, digital printing is additionally less inefficient and generally much more environmentally friendly.

("flexo"), involve several make-ready actions to move an original image to a substratum.

Examine This Report on 24??media

Digital printing, with less moving pieces, is much more dexterous than countered in this regard.

It's a means to blend your product packaging and advertising strategies. Decreased set-up time saves cash on the front end. And considering that these are not substantial mass orders, smaller sized businesses can afford to publish without having to satisfy the higher and extra costly print limits of standard printing. Digital printing helps safeguard your brand versus counterfeiting by including overt and covert solutions on your product packaging.

Be certain you collaborate with a printing and packaging companion that has the appropriate accreditations. While eleventh-hour printing and customization are a huge advantage, electronic might not always be the ideal approach for you. Counter printing has the benefit of cost-effectiveness with big print runs, especially those with innovative attractive effects and specialty finishes.

3 Simple Techniques For 24??media

The positive plate, with its smooth surface area, attracts oil-based inks and wards off water. In comparison, the adverse plate, with its rough texture, soaks up water and pushes back oil. Rubber rollers are after that used to move the photo from the plate to the corrugated surface area.

Corrugated paper can occasionally verify to be a tough surface area to print on, but Litho prints to a different surface area more helpful hints and is after that laminated flooring to it, making it easy to publish high-quality photos. It can be extremely regular, also for long runs. The extra you publish, the less expensive the prices become for Litho.

What Litho doesn't provide you is specifically what Digital does, customization. Costly established up Longer turn-around No Variable Data Printing Smaller sized color range, colors can be much less bright Digital printing is the procedure of printing digital pictures straight onto the corrugated substratum making use of a single-pass, direct-to-corrugate method.

Report this page